Basic Info.

Model NO.

DR-10000

Conductive Way

One-Sided

Welding Spot Number

Single

Type

Universal

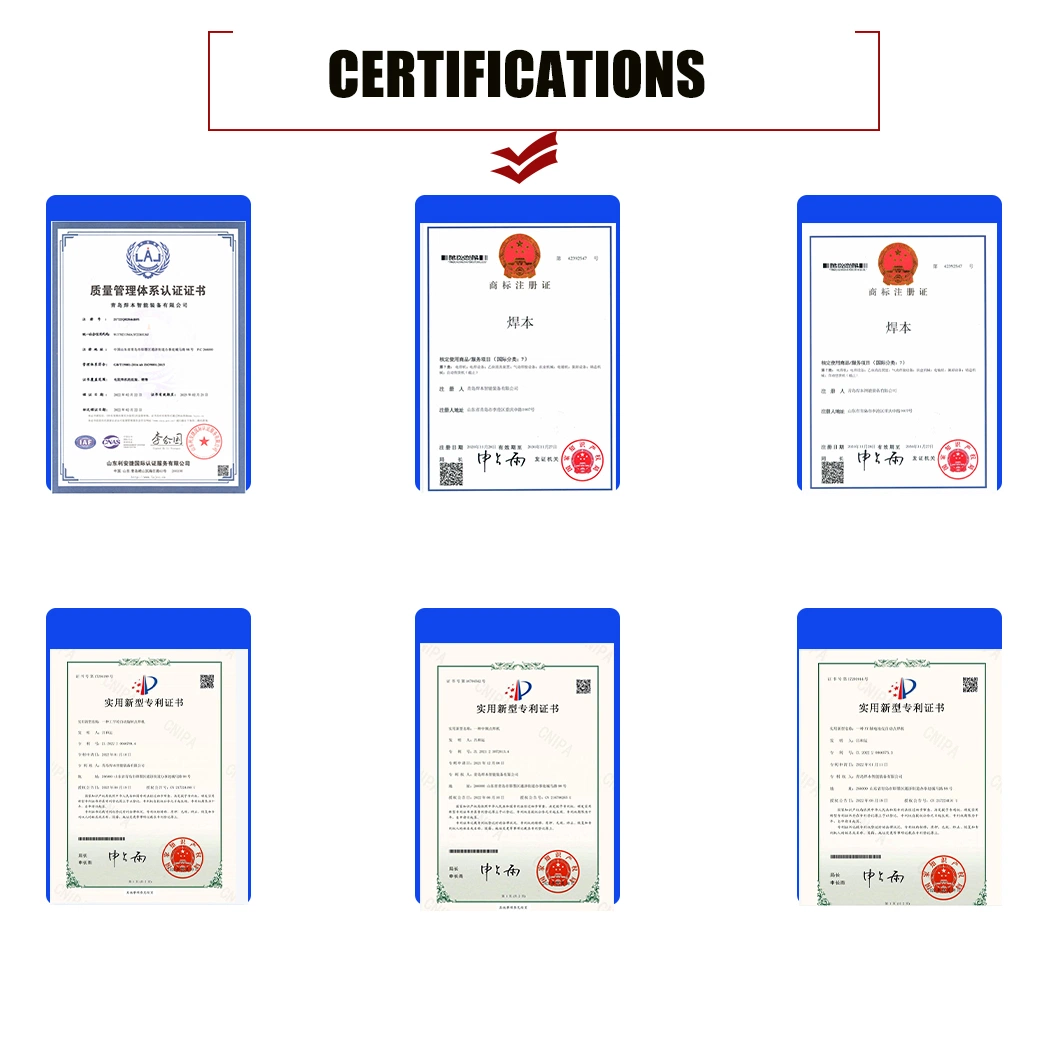

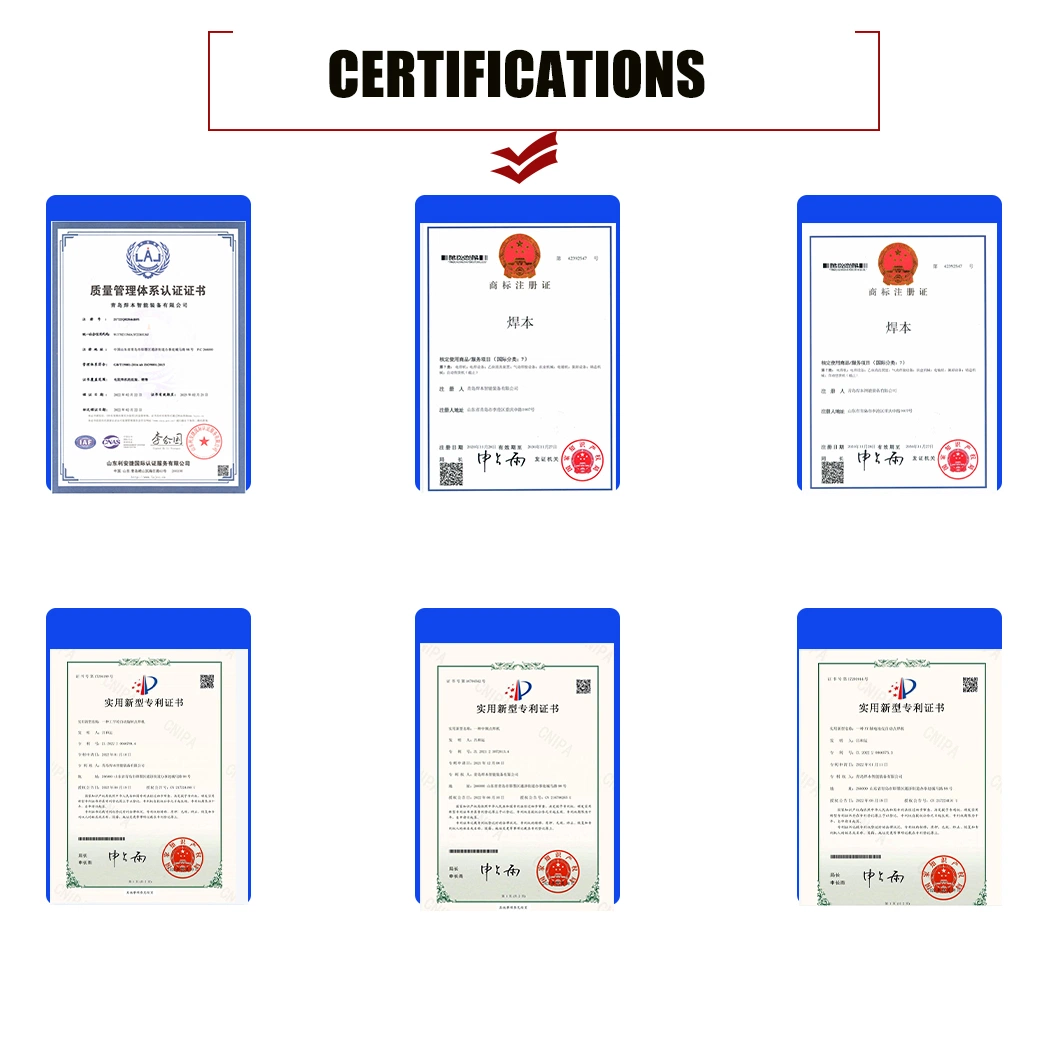

Certifications

CE ISO

After Sale Service

Online and Video Technology Support

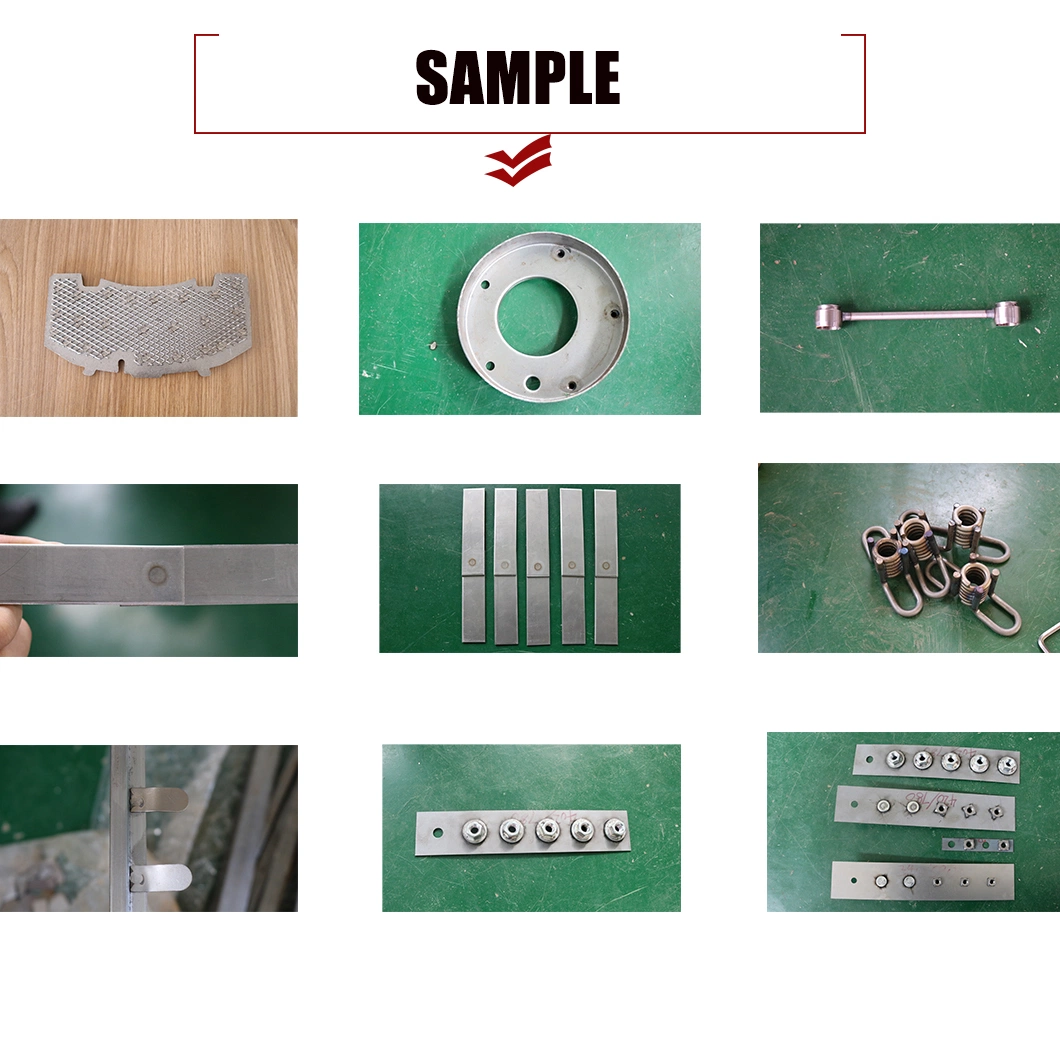

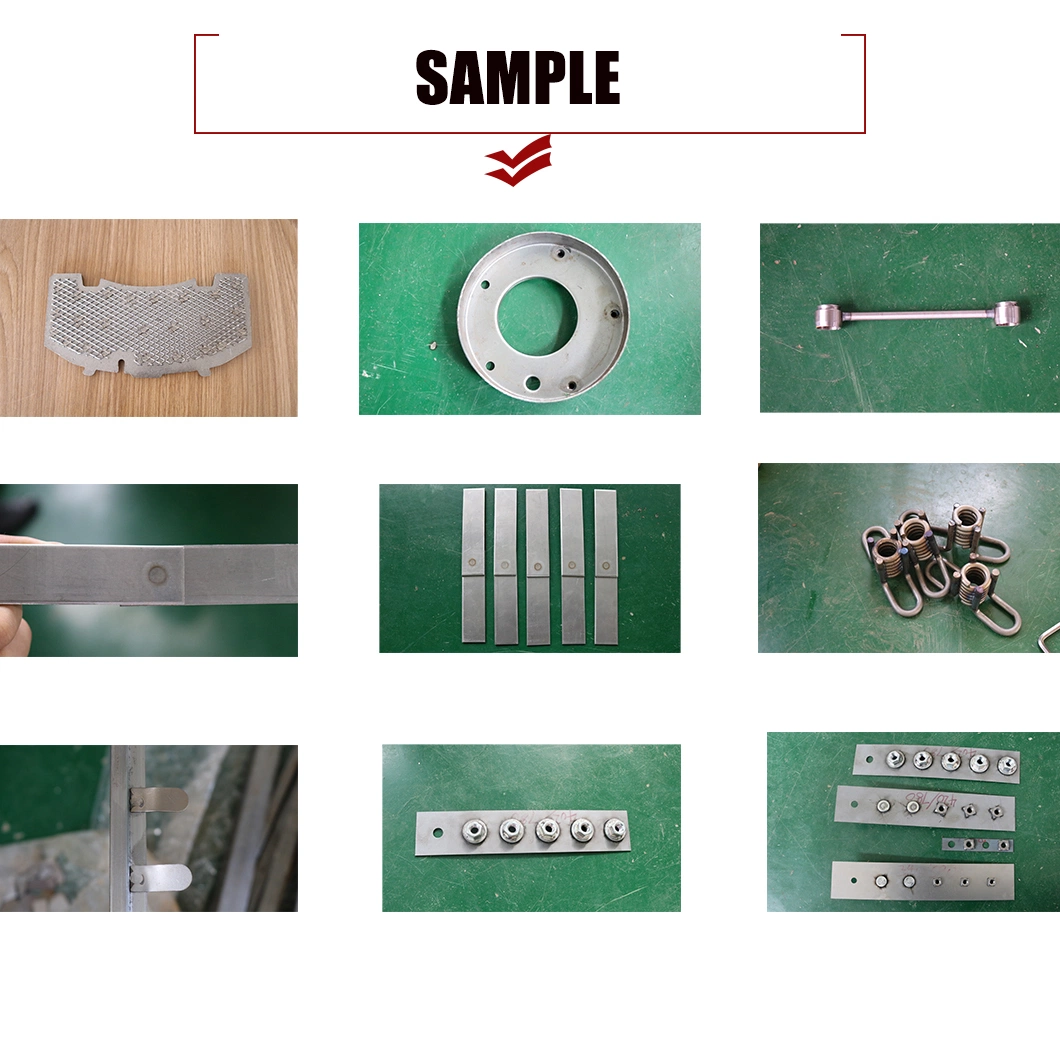

Applying to

Aluminium,Copper,Stainless,Galvanized

Product Name

The Capacitor Discharge Spot Welder

Transport Package

Wooden Case

Specification

1000kg

Trademark

Hanben

Origin

Qingdao, Shandong, China

HS Code

8468800000

Production Capacity

500

Product Description

Product description

Basic info.

Feature:

1 The capacitive energy storage welding method is adopted ,which makes the output current of the welding machine more accurate,has less impact on the grid,and is more energy-saving.

2 The imported world famous factory emergency vharging and discvharging capacitor is adopted,with stable capacity and long service life

3 Special cgarging circuit and control system design make charging faster and more stable

4 The surface of the solder joint is rarely oxidized and deformed,and the solder joint is not blackened,eliminating the need for polishing.

5 The welding time is very short,and the power on time is adjustable,generally only 0.003-0.006S.

6 Especially suitable for welding materials with large thickness differences

7 The output and input are completely separated,independent of external power supply changes,and maintain a constant power output

8 Widely used in bump welding and metal welding with good electrial and thermal conductivity.

FAQ:

1 Q: Do your factory sale directly?

A:yes,it is.Our factory sale directly,competitive price with high quality

2 Q;Can you export machines by your factory?

A:Yes,we can.

3 Q:Where are your factory?

A: Qingdao city ,Shandong province,China

4 Q: What do we need to do if the machine fails?

A:In the guarantee time (1 year),we will send the spare parts to you for free,and provide the technical consultant for any time.

5 Q:How long is the guarantee?

A:For one year after the custumer received the machine.

6 : Q:How is your quality control?

A:Strick quality control is performed in every procedure from material sourcing.

Basic info.

| projrct | power input | primary current | capacitance | load duration | deep throat | electrode stroke | electrode pressure |

| unit | V | A | UF | % | mm | mm | N |

| figure | 380 | 79 | 200000 | 50 | 390 | 80 | 12000 |

Feature:

1 The capacitive energy storage welding method is adopted ,which makes the output current of the welding machine more accurate,has less impact on the grid,and is more energy-saving.

2 The imported world famous factory emergency vharging and discvharging capacitor is adopted,with stable capacity and long service life

3 Special cgarging circuit and control system design make charging faster and more stable

4 The surface of the solder joint is rarely oxidized and deformed,and the solder joint is not blackened,eliminating the need for polishing.

5 The welding time is very short,and the power on time is adjustable,generally only 0.003-0.006S.

6 Especially suitable for welding materials with large thickness differences

7 The output and input are completely separated,independent of external power supply changes,and maintain a constant power output

8 Widely used in bump welding and metal welding with good electrial and thermal conductivity.

FAQ:

1 Q: Do your factory sale directly?

A:yes,it is.Our factory sale directly,competitive price with high quality

2 Q;Can you export machines by your factory?

A:Yes,we can.

3 Q:Where are your factory?

A: Qingdao city ,Shandong province,China

4 Q: What do we need to do if the machine fails?

A:In the guarantee time (1 year),we will send the spare parts to you for free,and provide the technical consultant for any time.

5 Q:How long is the guarantee?

A:For one year after the custumer received the machine.

6 : Q:How is your quality control?

A:Strick quality control is performed in every procedure from material sourcing.