- Overview

- Product Description

- Product Parameters

- Product Application

- Company Profile

- FAQ

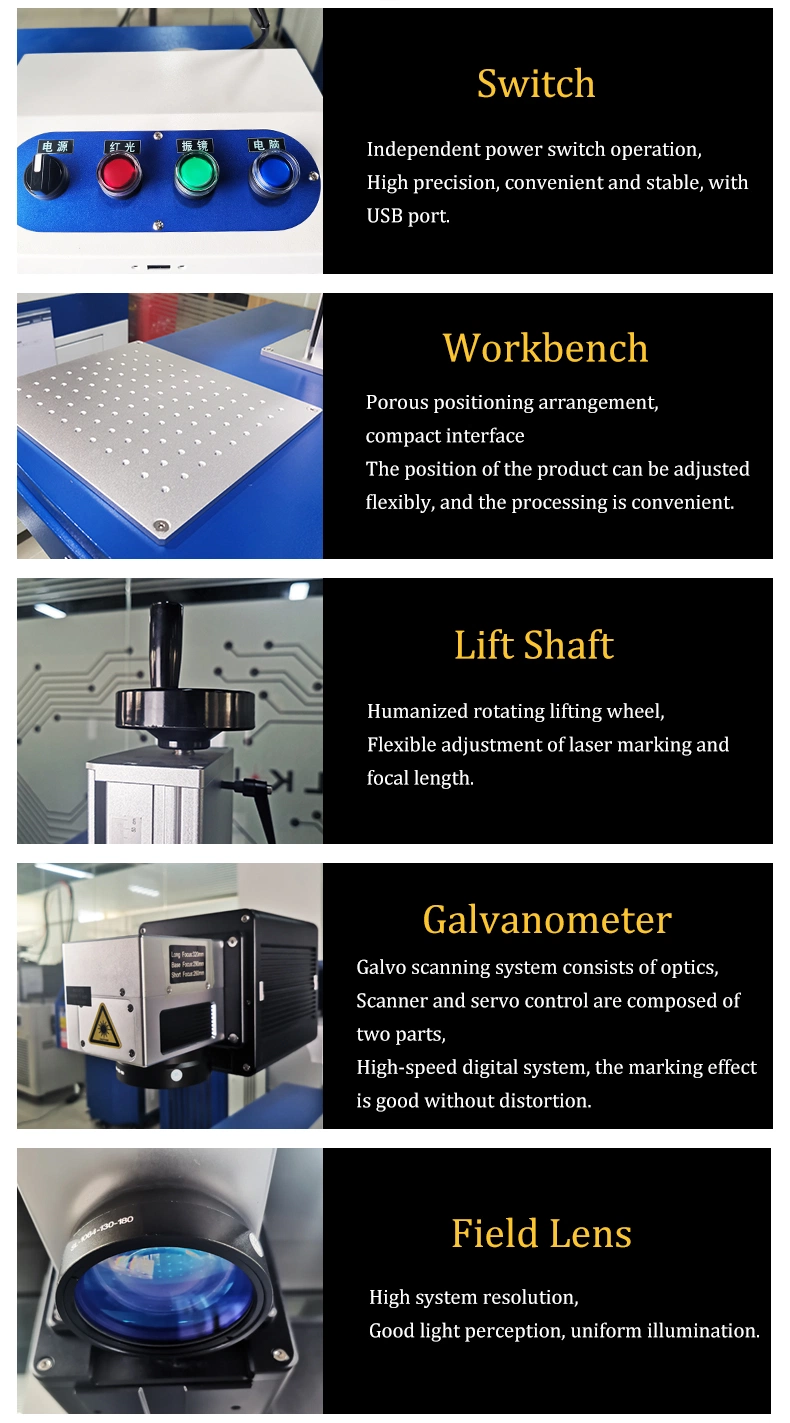

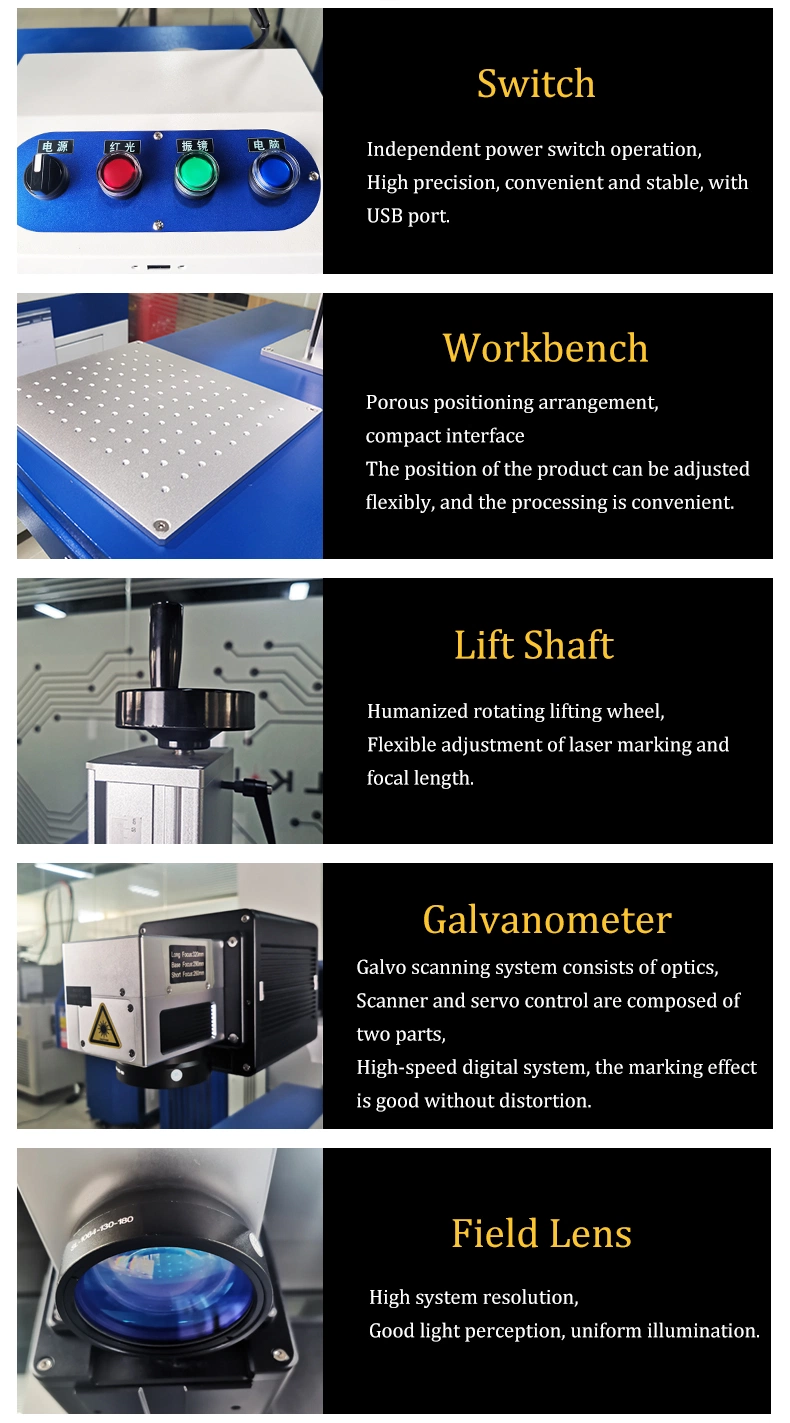

Basic Info.

Model NO.

LK-3D

Laser Wavelength

Fiber Laser

Laser Classification

Raycus

Type

Optical Fiber Laser Marking Machine

Marking Method

Mask Pattern Marking

Laser Power

20W-30W-50W-60W

Laser Wavelegth

1064nm

Laser Type

Raycus ( Can Choose Max/Jpt)

Mark Method

3D Dynamic Focus Marking

Marking Range

30*30mm to 300*300mm

Minimum Character

0.09mm

Engraving Line Speed

≤10000mm/S

Marking Depth

1mm

Q-Frequency

20kHz~80kHz

Power Supply

220V/50Hz

Transport Package

Wooden

Specification

700*600*1450mm

Trademark

LeiKang

Origin

China

HS Code

8443329090

Production Capacity

50/Week

Product Description

3D Laser Marking Machine

| Model | LK-3D |

| Laser Power | 20W/30W/50W/60W |

| Laser Wavelegth | 1064nm |

| Laser Type | Raycus/Max/JPT |

| Marker Method | 3D Dynamic Foucs Marking |

| Marking Range | 30mm*30mm-300mm*300mm |

| Marking Depth | 1mm |

| Engraving Speed | ≤10000mm/s |

Application Materials:

3D curved laser marking machine can accurately and efficiently mark on various complex

curved work-pieces. It is suitable for processing curved plastic, pig iron, stainless steel,

aluminum-magnesium alloy, aluminum oxide, copper, nickel plating, lamp, mold, 3C

electronic auto parts, electronic parts, craft gifts, etc.

3D curved laser marking machine can accurately and efficiently mark on various complex

curved work-pieces. It is suitable for processing curved plastic, pig iron, stainless steel,

aluminum-magnesium alloy, aluminum oxide, copper, nickel plating, lamp, mold, 3C

electronic auto parts, electronic parts, craft gifts, etc.

Welcome to Shenzhen Leikang Machinery Equipment Co., Ltd.! Our company has 13 years of experience in laser welding, laser marking, laser cutting, laser cleaning, laser engraving and laser cladding.

We have the ability to independently develop, produce, supply and sell laser machines. We can provide customers with customized services, and provide an efficient and advanced laser production chain, which improves customers' production efficiency and production capacity. LK Laser continuously strives to improve quality, technological innovation and production improvement, and enjoys a high reputation in the international market. Our customers are all over the world, such as: Australia, Pakistan, the United States, Singapore, the Philippines, Italy, India, Brazil, Egypt..

QI: I know nothing about the laser welding/marking/cutting machine, what kind of machine I should choose? Very easy to choose.

A1:Just tell us what's your application with using this machine. The Material you want to weld/mark/cut and how you want to weld/mark/cut? And sending us a sample picture is better. Then we will send you a perfect solutions and suggestions.

Q2: When I get this machine, but I don' t know how to use it. What should i do?

A2: We will send you the English manual and CD video for machine Using and maintaining with machine. If you still have some doubts, we can talk by telephone or skype. Our engineer can also be sent to your country to install or adjust machine if

nec-essary.

Q3:if some problems happened to this machine during war- ranty period, what should i do?

A3: We will supply free parts for this machine during the warranty period if machine have any problems.We also supply free af-terservice forever. So any doubts, just letus know, we will give you solutions within 30 min.

Q4: How long is the delivery time?

A4: Usually delivery time will be 5-7 days ,and if customization ma- chine will take 1 5-20days

Q5. How about the packaging?

A5: Firstly, Packed the fiber laser machine with plastic sheet for clearing and damp proofing.

Secondly, Then put the fiber laser machine in the plywood case for safety and clashing. Thirdly, Transport the plywood case into the container.